Business Areas

Best technology in clean hydrogen energy, high pressure gas, disaster prevention business, safety equipment

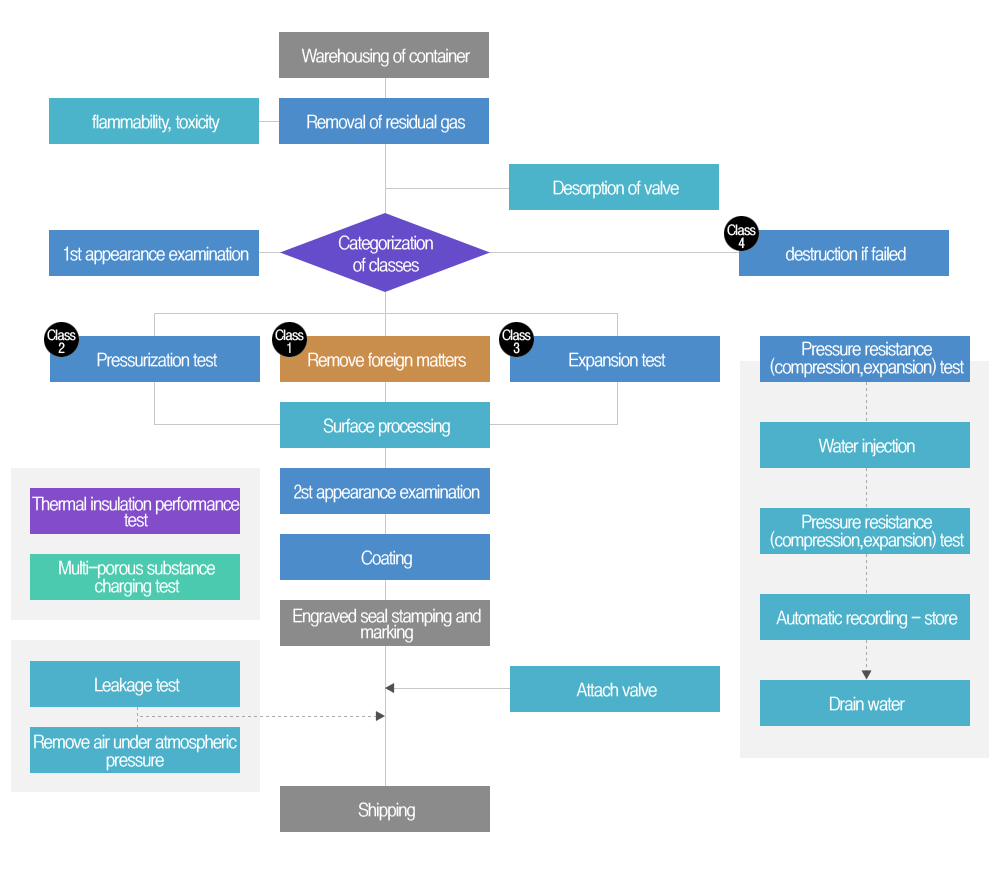

Retest Of High Pressure Gas Cylinder

All pressurized gas containers must be used by undergoing regular retesting at the interval of 3~5 years by specialized testing institution in order to prevent danger of pressurized gas and to ensure safety of the public.

Test Specifications

| KGS (Article 35 of the law on pressurized gas safety management) | AC 218 | Less than 3,000L of container without joints (including cartilage container) (including toxic gas) |

|---|---|---|

| AC 217 | Less than 200L welding (acetylene, cryogenic) container (excluding toxic gas) | |

| AC 414 | Less than 200L general composite container | |

| AA 316 | Container component parts for pressurized gas | |

| DOT (DOT 49CFR 173.34 & CGA Pamphlet) | DOT-3AA | Seamless Cylinder - Max. Water Capacity 453L Min. Service Pressure 150 psig |

| DOT-3AAX | Seamless Cylinder - Min. Water Capacity 454L Min. Service Pressure 500 psig |

|

| DOT-3T | Seamless Cylinder - Min. Water Capacity 454L Min. Service Pressure 1,800 psig |

Name of Designated Tests

| Types of container | Types of gases | Content volume |

|---|---|---|

| Seamless cylinder | Oxygen, nitrogen, argon, hydrogen and carbon gas, etc. General pressurized gas and special gas container |

1 ~ 125 L |

| Large sized container(√Є750 x 3500 mm) Cartilage container(√Є789 x 11541 mm) | more than 125 L | |

| Composite materials container (exclusion of composite materials container without liner and composite materials container with plastic liner) | Less than 450 L | |

| Welded cylinder | Cryogenic container (Oxygen, nitrogen, argon, Freon and helium) | Less than 500 L |

| Acetylene container | Less than 80 L | |

| Container component parts | Valve for container and other component parts for the containers for compressed natural gas for automobile with size exceeding 125L | - |

| Container component parts with built-in diaphragm | ||

| Container component parts for general industrial pressurized gas, and inhalation of air and oxygen |

Pressurized Gas Safety Management act

Period Of Retesting

вАї You can check by swiping the table left or right (swipe).

| Types of containers | Period of retesting | |||

|---|---|---|---|---|

| No. of years after the new testing | ||||

| Less than 15 years | 15 ~ 20 years | More than 20 years | ||

| Welded cylinder (with the exclusion of container for liquid petroleum gas welding) | More than 500 L | 5-year interval | 2-year interval | 1-year interval |

| Less than 500 L | 3-year interval | 2-year interval | 1-year interval | |

| Seamless cylinder and composite material container | More than 500 L | 5-year interval | ||

| Less than 500 L | 5-year interval for those with less than 10 years since the new testing, 3-year interval for those with more than 10 years | |||

| Container component parts | Those not attached to the container | Prior to the attachment to the container (corresponds only to those that have been more than 2 years since the last testing) | ||

| Those attached to the container | After 2 years of the testing, whenever the container to which the component part is attached is being retested | |||

| вАї References 1) Composite materials container and container for the compressed natural gas automobile will be discarded after 15 years from the date of the manufacturing testing. 2) Component parts excluded from the application of useful lifespan A) Valve for medical gases stipulated under KS B 6214(pressurized gas container valve) B) Container component parts for inhalation of air and oxygen |

||||

Container Without Joints

Current Status Of Facilities Owned

¬Ј Water recharging facility

¬Ј Pressure resistance facility installation

¬Ј Steam, drying and drainage facility

¬Ј Short blast facility

¬Ј Coating (undercoating and top coating)

¬Ј Heated drying facility

¬Ј Natural drying facility

¬Ј Press facility

¬Ј Detachment and attachment device for valves

Information On Product Testing

NKTECH Co., Ltd., an institution specializing in gas testing, executes not only retesting of the industrial pressurized container but also retesting of ultra-large container and air respirator container as well as retesting of valve for special gas container with built-in diaphragm. Having established ourselves as an institution specializing in testing of pressurized container and container valves, we shall ardently strive to remunerate the passionate support our clients have given us by assertively fulfilling the requirement of our clients..